Anti-oil pollution treatment purpose

In addition to the general waterproof and breathable functions, waterproof and breathable membrane products are designed to improve protection in more severe environments (such as filled with oil/oil stains and other highly polluting liquids), increase the service life of customer products, and reduce the maintenance and use costs of customer products. .The oil stain in the picture only uses engine oil as the test oil. For the introduction of oil-proof grades, please refer to the information below.

When oil comes into contact with the surface of the oil-proof film

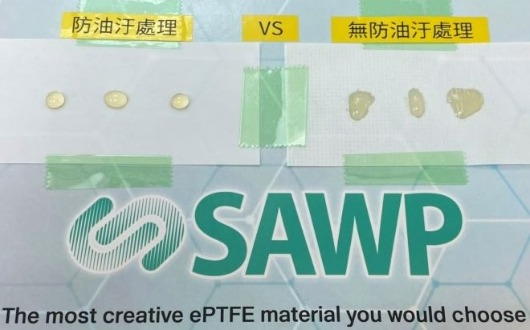

How to tell whether the surface of the film has anti-oil treatment? After dripping oil, observe whether the shape of the oil collapses or takes on the shape of water droplets, as shown in the picture on the right.

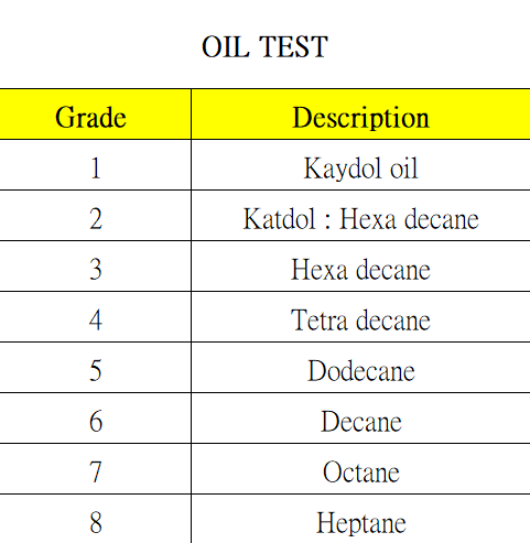

Specifications and descriptions of oil-proof grades

The oil-proof grade is mostly defined according to the AATCC118 specification. The "Oil Drainage" Hydrocarbon Resistance Test" measures the oil-proof properties of fabrics. Eight kinds of homologous solvents with gradually decreasing surface tension are used as standard liquids, and different grades of test liquids are tested. Drop it on the surface of the material and observe the surface wetness after 30 seconds. If the final test solution does not wet the material, then this grade of solvent is the oil-proof grade of the material.