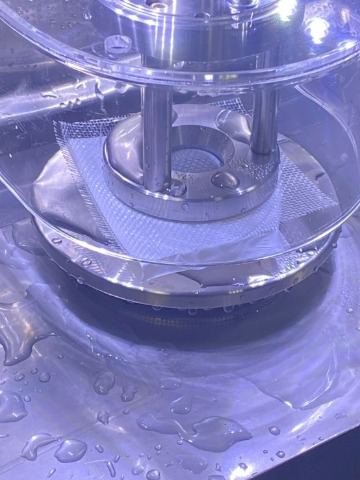

Water pressure test

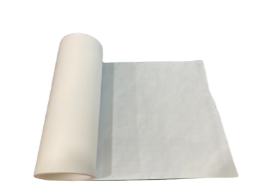

Raw material testing area

The raw material testing area is divided into a circular chuck with a diameter of 11.28 cm and a chuck with a diameter of 3 cm for testing.

Raw material inspection unit

The most commonly used unit is mmH2O

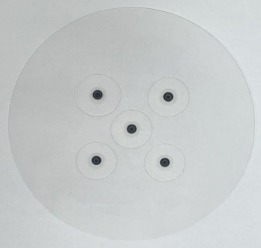

Different finished size test

We can provide customers with a simulated area test, as shown in the clip below, the black part is the size of the customer's use area.

The testing of raw materials is mainly aimed at the quality inspection when the material is purchased/the inspection report when it is shipped, and it can ensure that there are no problems and meet the specifications in both incoming and outgoing materials.

The simulation test is mainly to reduce customers' doubts, and also reduce the time of customers in the verification stage. I believe it can help customers to have more confidence when using our products.

Schematic diagram of water pressure detection

From left to right are composite material detection - pure membrane detection - small size simulation detection.

The test area of the drawing fixture is a circle of OD 3CM